Active Network Management using Real Time Fault Level Results

National Grid Electricity Distribution (NGED)

Outram Research have been working with NGED since 2012 to maximise the benefits of their unique Fault Level Measurement technology within the Electricity industry.

While Outram Research have already produced a portable Fault Level Monitor able to generate Fault Level results from natural disturbances through a previous project with SP Energy Networks, NGED then devised a new project to design and put together a Fault Level Monitoring unit capable of creating it’s own disturbances. Rather than waiting for an accumulation of data to give a reliable Fault Level (Short Circuit Current) answer, the results from the new unit would be generated fast enough to facilitate active network management based on the actual Fault Level, not just pre-calculated models.

Tier 1 Low Carbon Networks Fund (LCNF) From OFGEM

Between 2012 and 2014 National Grid Electrical Distribution (NGED) ran an OFGEM funded Project called ‘Implementation of an Active Fault Level Management Scheme’ (link https://www.westernpower.co.uk/innovation/projects/active-fault-level-management-scheme)

The aim of this project was to put together various components available in the market in order to make an Active Fault Level Monitor. The project was to combine our Outram PM7000FLM, an S&C Intelliruptor and a Nortech Envoy to create a device capable of producing and communicating Fault Level results in near real time.

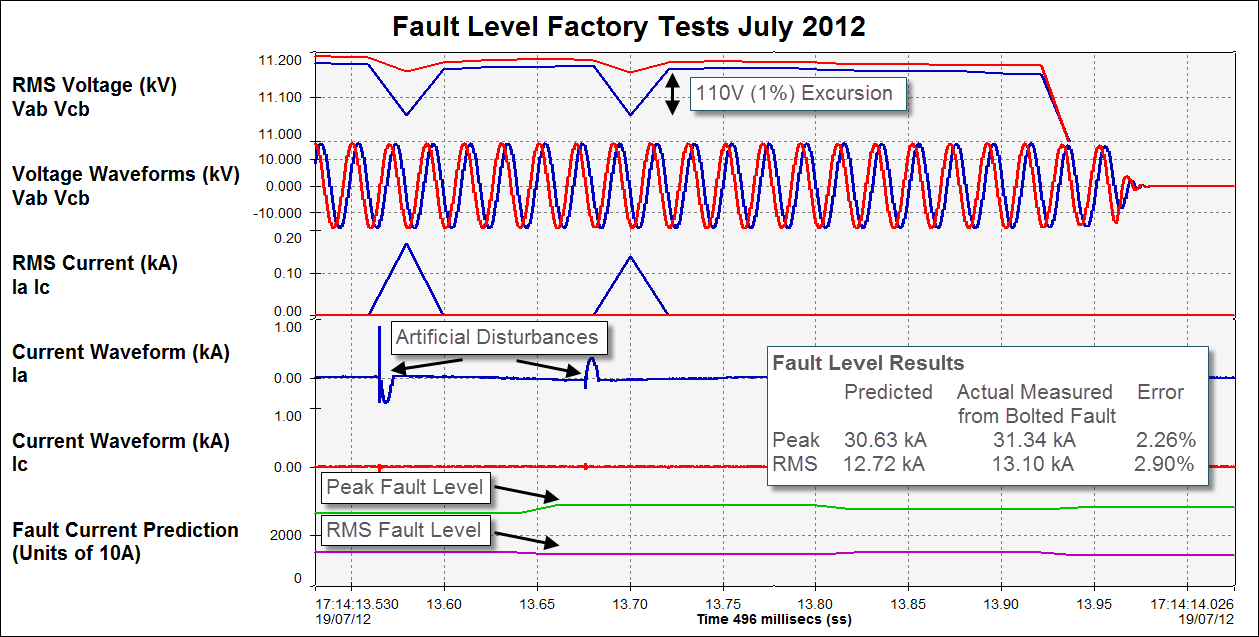

Phase one of their Tier 1 LCNF project involved laboratory trials comparing the predicted fault level with the actual measured peak current seen in response to a bolted fault. These trials were very successful, the results showing that the Active FLM predictions were between 2.5 and 5% of the current measured by lab instrumentation – an inevitable error margin dependent on noise on the network and sensor deficiencies which are likely to produce some degree of uncertainty.

“Real-time fault level monitoring will be used to manage the connection of a distributed generator to increase the power supplied from renewable energy resources and to manage the fault level to avoid exceeding equipment ratings.”

LCN Fund First Tier Pro Forma, 2012

Please click here for more details on the results of Phase 1 of the project.

Phase 2 involved the implementation of this Active Fault Level Monitoring device onto the network to control the connection of a distributed generator. Following successful field trials, the results of which can be viewed in the project closedown report here: https://www.westernpower.co.uk/downloads/2350, the AFLM System (known going forward in this context as an FLM) was to be used in NGEDs next project, FlexDGrid.

Active Network Management using Fault Level: A Tier 2, Low Carbon Networks Funded project, FlexDGrid

Once the smaller scale trials had been completed, NGED incorporated Real Time Fault level measurement into their larger scale project. The objective of the project was to use fault level measurement to actively manage the demand within 11kV (HV) electricity networks and reduce the time and cost associated with connecting distributed generation. They did this by developing new fault level assessment processes and deploying alternative mitigation solutions as a result of real time monitoring of fault levels.

NGED’s ultimate aim was to further develop their ability to actively manage their distribution network by optimising the network arrangement using predicted fault level values.

“Relevance and timing. This project is highly relevant. Fault level is a major barrier to the connection of distributed generation in some situations. A greater understanding of the need for fault level mitigations, and providing alternative mitigations, could lead to significant cost reductions and is clearly relevant to DNOs. NGED has seen an increase in fault level related expenditure and this could rise significantly in the RIIO-ED1 period and beyond. The Flexgrid methods could be used as an alternative to network reinforcement, impacting significantly on this expenditure, and become a crucial part of business planning.

The connection of distributed generation (DG) in the near future, in particular Combined Heat and Power (CHP), is highly likely and as such this project is very timely.”

Innovation in networks – Ofgem’s Low Carbon Networks Fund. Decision on third year competition

FlexDGrid Project: Money savings, increased capacity and increased customer flexibility

While the full results from the FlexDGrid project can be viewed in the NGED Closedown report here, we have pulled out some of the sections of the report highlighting the benefits of measuring Prospective Fault Level in real time.

“This [operation, using FLM data] can [save] in the region of £145k per MW of generation connection…”

“Having made the real-time Make and Break Fault Level values readily available through the installation of the 10 FLMs, the second output focused on the development of procedures and systems to both enable customers to engage in alternative connections and for DNO control engineers to dynamically operate the network. One example was the ability to operate the network in parallel configuration, when the FLM data shows the values to be below the acceptable limits. This learning can demonstrate a saving in the region of £145k per MW of generation connection.”

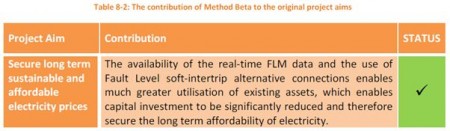

“This enables the deferment and avoidance of capital investments and therefore assists the secure long term sustainable and affordable electricity prices.”

“These outputs, of both the installation of the FLMs and FLMTs, supported the reduction in long connection lead times for the connection of low carbon generation, through alternative connections facilitated by the real-time FLM data. The ability to dynamically operate the network based on the FLM real-time data and the installation of the three FLMTs has enabled the increase in the network efficiency through the reduction of CIs and CMLs respectively, where the network can now be operated in parallel. Through the delivered outputs in all three methods, and the combination of methods, additional options and tools have been provided. This enables the deferment and avoidance of capital investments and therefore assists the secure long term sustainable and affordable electricity prices.”

p10 Western Power Distribution FlexDGrid Project Close Down Report June 2017

“It was predicted that up to 10% capacity could be released [from a DG plant]…”

“Method Beta aimed to increase understanding and management of Fault Levels through the installation of real-time Fault Level measurement devices, specifically those developed under the NGED LCNF Tier-1 project “Implementation of an Active Fault Level Management Scheme”, at ten Primary Substation sites. This enabled accurate Fault Level data to be gathered for various network running arrangements, providing verification of the Fault Level assessed in Method Alpha. This allowed the 11kV network configurations and the status of DG plant to be monitored on a more granular level. It was predicted that up to 10% capacity could be released through this Method.”

p17 Western Power Distribution FlexDGrid Project Close Down Report June 2017

Give customers a choice

“…Increase network security and … facilitate additional, otherwise unfeasible, customer connections.”

“Following the installation of the FLMs and the acquisition of Make and Break Fault Level values it was possible to enable the network to be operated based on these values, both to increase network security and to facilitate additional, otherwise unfeasible, customer connections.”

“…use…the real-time Fault Level data to determine…whether a generator can remain connected to the network or must be removed”

“This enables the use of the real-time Fault Level data to determine, based on an appropriate safety factor (as detailed in SDRC-11), whether a generator can remain connected to the network or must be removed due to a potential Fault Level rating infringement. Analysis, again detailed in SDRC-11, evidenced that a generator is likely to experience around three signals to disconnect from the network each year for an average of four minutes.”

p26 Western Power Distribution FlexDGrid Project Close Down Report June 2017

Further uses of Fault Level Data

“Using artificial and natural disturbance data along with load and voltage information, it was possible to calculate the MVA/MVA Fault Level infeed at a given substation.”

“Collected Fault Level data that was fed back into models developed in Method Alpha informed updates to planning Fault Levels. Using artificial and natural disturbance data along with load and voltage information, it was possible to calculate the MVA/MVA Fault Level infeed at a given substation. By breaking down the load types using metering data, it was possible to determine the Fault Level infeed based on the generic load type”

p27 Western Power Distribution FlexDGrid Project Close Down Report June 2017

“This information is now being utilised by system planners for informing capital investment plans and for the planning of generator connection options…. In turn this will lead to a dramatic reduction in the lead times for connection of low carbon generation in Fault Level constrained networks.”

“The installation and operation of FLMs has provided greater understanding and granularity of existing Fault Levels in Birmingham. The information and data being collected has been integrated into NGED main business providing both real-time and historic Fault Level information. This information is now being utilised by system planners for informing capital investment plans and for the planning of generator connection options. The inclusion of Fault Level soft-intertrip within NGED’s alternative connections policy means that a standard system is in place for the connection of customers based on the real-time data of the FLM.

This type of constrained connection would enable customers to connect without the need for major capital investment works. In turn this will lead to a dramatic reduction in the lead times for connection of low carbon generation in Fault Level constrained networks. The ability to allow greater penetration of Low Carbon Generation and CHP units within fault limit constrained networks will assist in securing long term sustainable and affordable electricity.

The FLM data is available in real-time to control engineers. This allows the network condition to be monitored and switching decisions made based on controlling Fault Levels. This enables switching to reduce potential CIs and CMLs through paralleling of the network or the safe transfer of loads under fault conditions.”

p37 Western Power Distribution FlexDGrid Project Close Down Report June 2017

Appeal for the next Outram development: the Real Time Fault Level Monitor (RTFLM)

With the encouragement of these very successful trials, Outram have already designed and are testing in Chester, UK, a new design of Real Time Fault Level Monitor, which uses power electronic switching.

See below the quotes from the Closedown report that both describe the absolute value of using a real time fault level monitoring system for Active Network Management and the potential improvements that could be made to the existing FlexDGrid FLM design.

“Based on the learning generated from the project,…, it is expected that for the installation of a [FlexDGrid} FLM there would be a reduction of 20% meaning £165k per install**. This would typically enable 3MW of generation on a flexible basis meaning a saving of £435k based on £200 per kW connections as per the charging methodology.”

p49 Western Power Distribution FlexDGrid Project Close Down Report June 2017

“Whilst the technology deployed as part of FlexDGrid is scalable, robust and accurate, further development would provide even greater flexibility in terms of the locations of installations and applications and it is likely that this further development would be required to enable wider deployment of FLMs on the system.

Two potential future applications have been identified. Firstly, a mobile FLM** that can be moved between sites providing short term monitoring to assist in identifying Fault Level issues. The second is the development of a Power Electronic FLM**. This is likely to have a smaller footprint than the current technology enabling easier installation at a wider range of substations. Both options would minimise interfaces with existing equipment with potential benefits being a lower installation cost, improved accuracy and reliability. The technical policies for staff to utilise these solutions for the benefits of customers, as described above, are readily available.”

p51 Western Power Distribution FlexDGrid Project Close Down Report June 2017

**The foot print is indeed smaller, as predicted by NGED, and the cost of installation significantly less than the £165k mentioned of the AFLM system in this trial. For more information on the RTFLM, click here or please contact us.